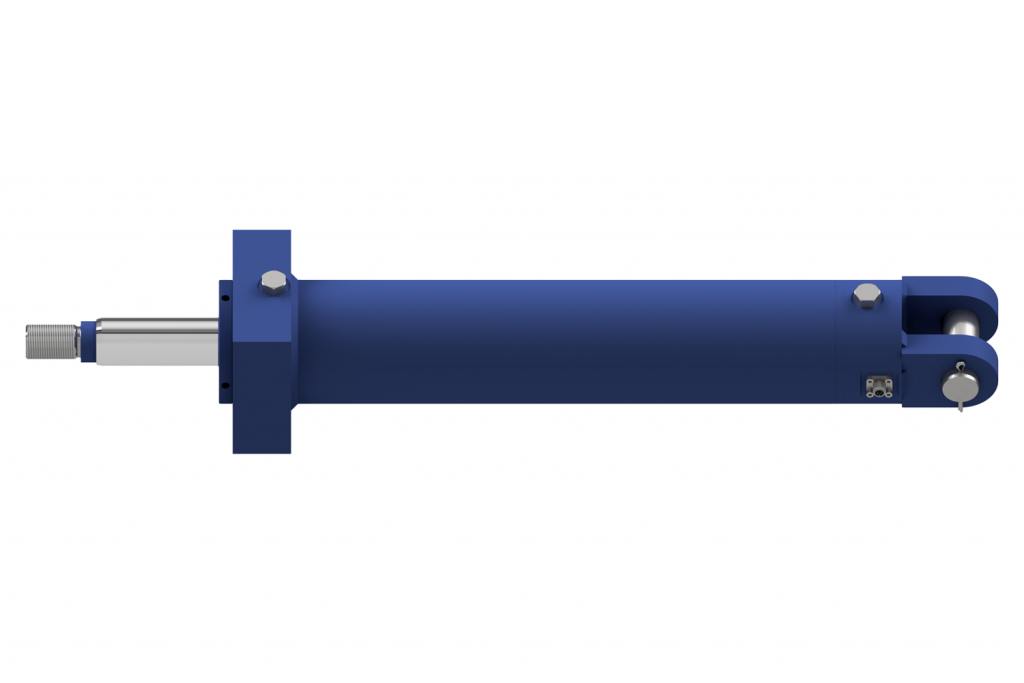

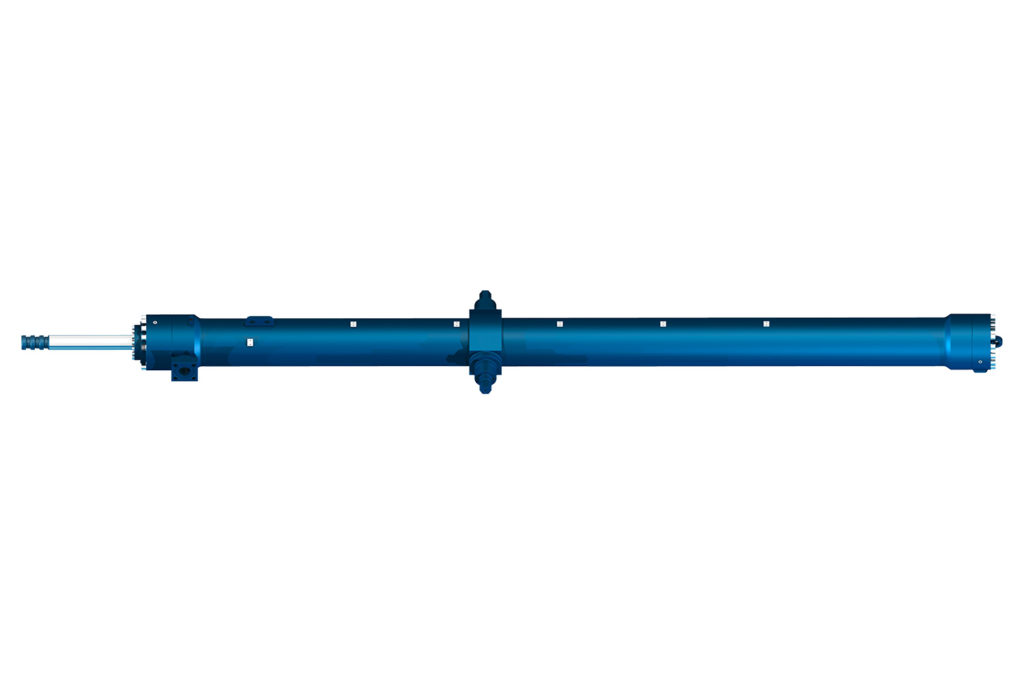

There are no climatic limits to the exploitation of oil and natural gas. The Montanhydraulik Group develops hydraulic drive concepts consisting of cylinders, hydraulic aggregates, and control concepts for the oil and natural gas industry. Safety and reliability for humans combined with on-site technology are the fundamental requirements for the use of oil hydraulics in the oil and natural gas industry. Whether at arctic ambient temperatures of -50° C, temperatures up to 60° C in desert regions, on land or on the high seas, the functions must be implemented precisely, and performance must be optimised every time. Our numerous cylinder applications in the off-shore sector and our hydraulic drive systems for complete drilling rigs are designed for these operating conditions. For fully automated, fast, safe and efficient raising of the mast and sub structure of land drilling rigs, the Smart Rig System offers a turnkey lifting solution for mast and substructures. The system consists of double acting telescopic cylinders with integrated position feed system, load sensing system, computerised control unit and manifold block.

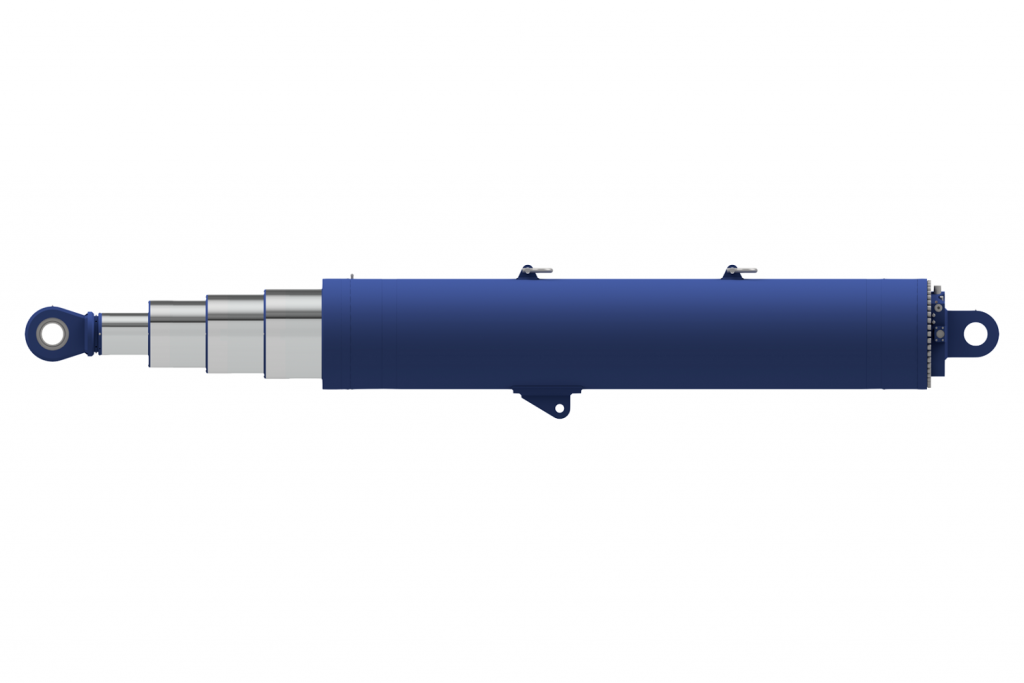

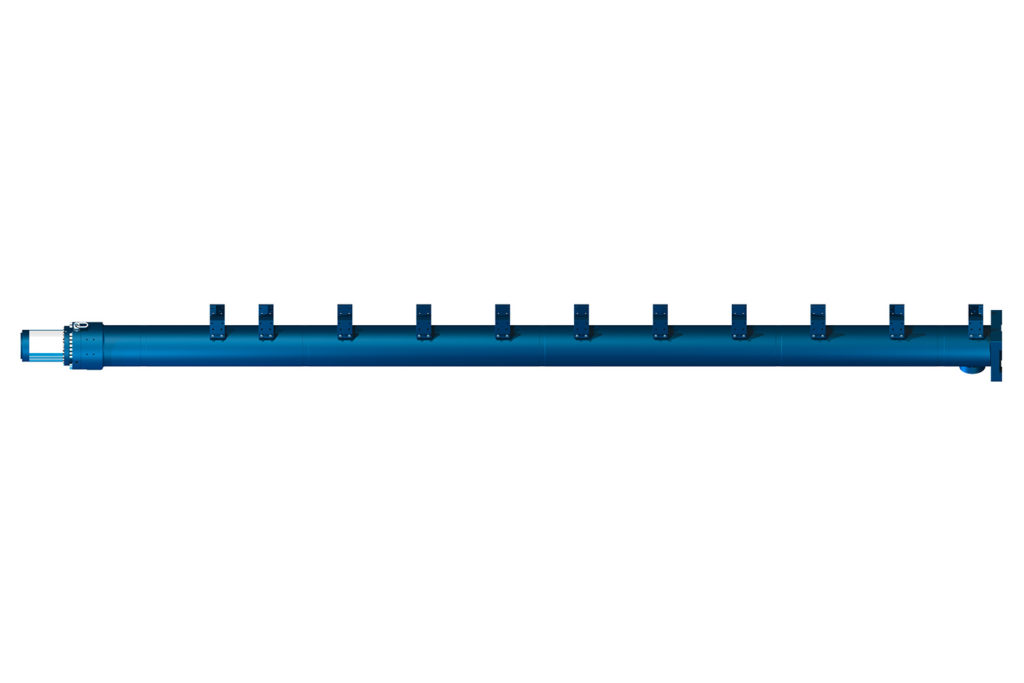

Due to the development of the land Drilling rig walking system, the rig can „walk“ from one drilling position to the next without disassembly. Montanhydraulik Group designs and delivers the required cylinders for this system.

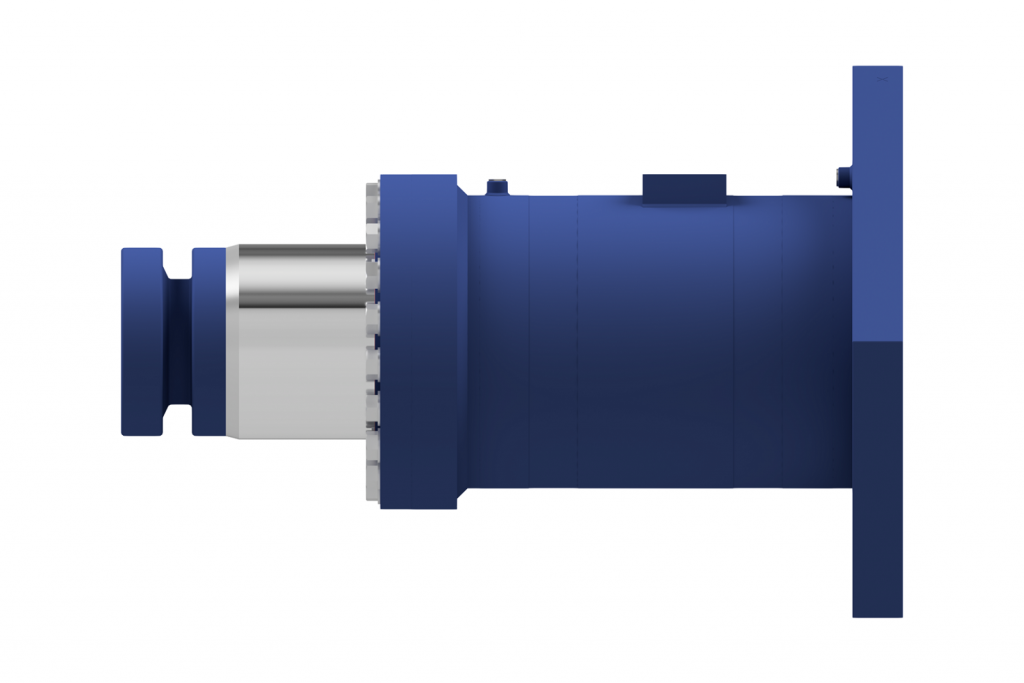

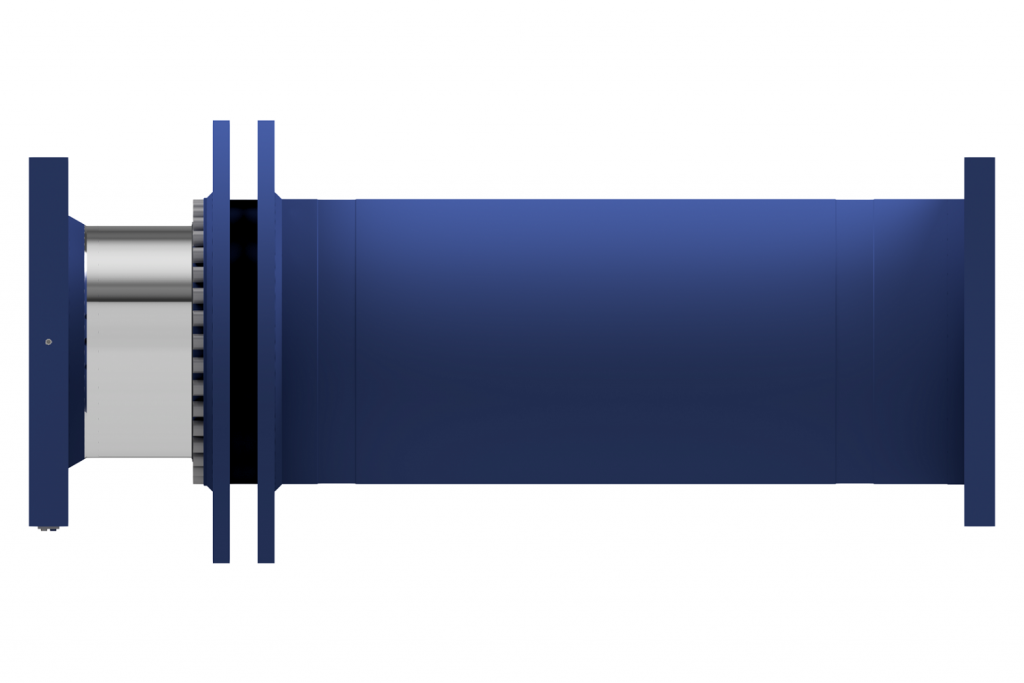

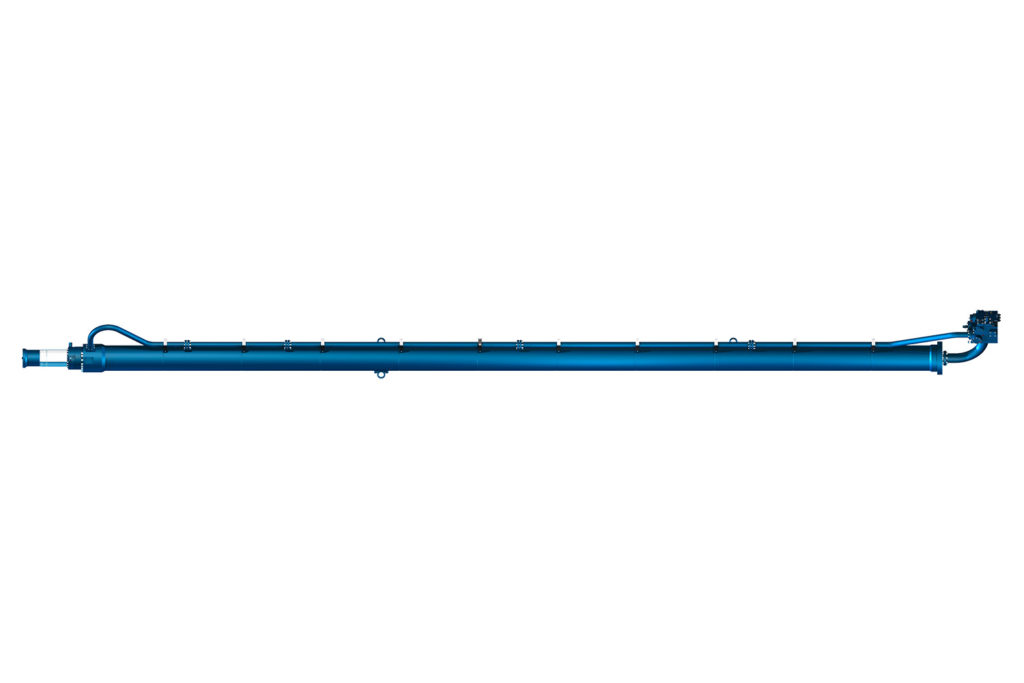

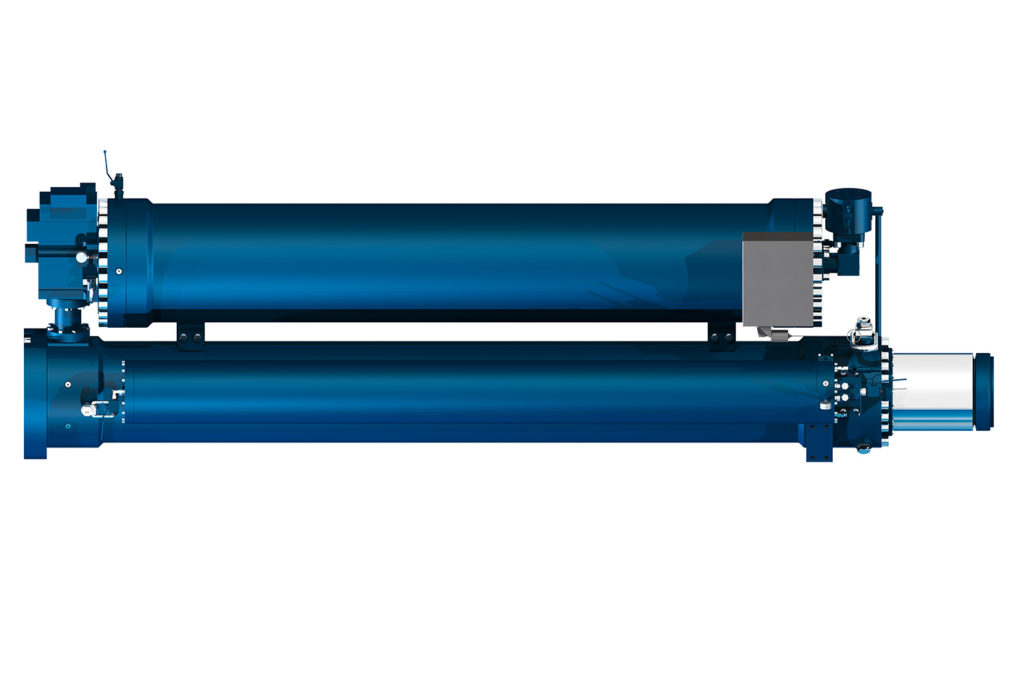

For off-shore drilling ships, Montanhydraulik Group delivers the hydraulic components for crown mounted compensating systems, active heave compensating systems and wireline tensioning systems for swing compensation. In addition, for the biggest ship cranes with 800 tons lifting power, Montanhydraulik deliveres the main cylinders and the knuckleboom cylinders with an outside diameter of 720 mm and a total weight of 32,000 kg and 29,000 kg.