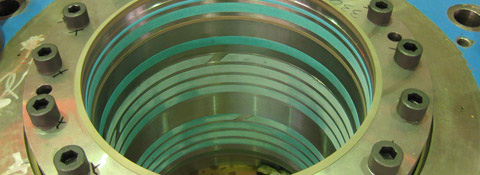

It was the first repair of the steering cylinder since the BG 285 bucket wheel excavator was built in 1975. Wear, combined with enormous impact forces, had completely destroyed the piston sealing system and the sealing material. The axial holding rings for the piston seal had come away from the piston and were jammed in the cylinder bore. Because of the serious leakage through the disintegrated piston sealing system, the forces required to move the steering shaft could no longer be applied. The digger could not be manoeuvred.

Because Montanhydraulik Repair and Service had already successfully repaired two similar cylinders in the past, the repair company was also engaged to repair this steering cylinder. For this, the greatest challenge was the piston rod head. Initially shrunk onto the rod through heating and cooling, in order to transfer tensile forces of 10,000 kN, it had to be removed in the same way, so as to be able to dismantle the cylinder weighing 45 t. In fact three attempts were necessary, requiring ten hours of patience and a certain amount of technical creativity, until the six ton rod head could be loosened with the aid of hydraulic pressure and by heating the rod head to 300 ºC

Good collaboration with Montanhydraulik in Holzwickede

It was then clear that the 610 mm length and 500 mm fitting diameter of the two parts were heavily grooved, and that there were numerous deep seizure marks. However, through the support of Montanhydraulik in Holzwickede, the repair lasted only one day longer than planned. For the necessary turning tasks, the technicians first built a steady-rest which was freely adjustable on the piston rod, and reduced the diameter of the rod by 4 mm. They then welded the reduced diameter up to size using submerged arc welding, and machined it again to the true diameter. The rod head was machined to +0.5 mm. The work required the greatest precision, because the press fit had to be created as per the original pattern, so that the tensile forces could again be fully transferred without any problems.

Vertical cylinder installation

The final obstacle was to shrink the rod head back onto the piston rod in such a way that the press fit could be used to its full extent and that the repaired steering cylinder would guarantee the problem-free operation of the bucket wheel excavator. For the installation of the cylinder, the piston rod with piston and cylinder head were suspended from a 300 t mobile crane hook lowered through the opened roof of the manufacturing hall. Beneath this was the vertically aligned rod head, mounted in a steel frame; this was again heated to 300 ºC, while the fitting diameter of the rod was cooled to –150 ºC using liquid nitrogen. The piston rod was then lowered little by little into the rod head. After successful function and pressure testing, as well as filling with 3,500 litres of hydraulic oil, the steering cylinder was finally transported back to the customer on a special low-loader – punctually and maintained to be as good as new.

These requirements were successfully fulfilled:

- Maximum repair time of 3.5 weeks

- Installation capacity suitable for cylinder weight and size

- Manufacturing capacity for replacement parts having 1,000 mm diameter

- Replacement and optimisation of the sealing and guiding elements

- Renewal of the fit between piston rod and rod head

- Refurbishing and repolishing of the chroming on the piston rod

- New sealing of the cylinder, even when dimensions changed because of repairs

- New manufacture of six holding rings for the piston seal (ø 1,000 mm), a seal for the guide bushing, and the bronze piston (ø 1,000 mm)

- Honing the cylinder bore

- Inspection and repair of the valves fitted to the cylinder

- Installation of valve connection plates and adjustment of the pipework to implement the installation locations of the valve blocks

- Pressure testing and filling with hydraulic oil

- Renewal of the paintwork on the cylinder as per customer requirements for corrosion protection coatings, including sand blasting

Technical data for hydraulic cylinder:

- Weight: 45 t

- Piston diameter: 1,000 mm

- Rod diameter: 500 mm

- Total stroke: 4,400 mm

- Oil capacity approx. 3,500 l

Technical data for bucket wheel excavator:

- Year built: 1975

- Service weight: 13,500 t

- Rated supply capacity: 200,000 m3/day

- Length: 210 m

- Height: 92 m

- Chassis width: 45 m

- Number of crawlers: 12

- Drive power: 16,560 kW